MAANSHAN ARCOROM MACHINE TOOL CO., LTD

Steel forming specialist

Cold Chamber Die Casting Machine

Quick Details

Type: Horizontal Die Casting Machine Machine type: Electric control

Condition: New Brand Name: Arcorom

Model Number: HC Serials Warranty period: Lifetime warranty, one year free

Certificate: CE Quality system: ISO9001-2000

MOQ: 1 Unit After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery Packaging Details: film or wooden box

Delivery Detail: 30-60 days after deposit payment.

Type: Horizontal Die Casting Machine Machine type: Electric control

Condition: New Brand Name: Arcorom

Model Number: HC Serials Warranty period: Lifetime warranty, one year free

Certificate: CE Quality system: ISO9001-2000

MOQ: 1 Unit After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery Packaging Details: film or wooden box

Delivery Detail: 30-60 days after deposit payment.

Features

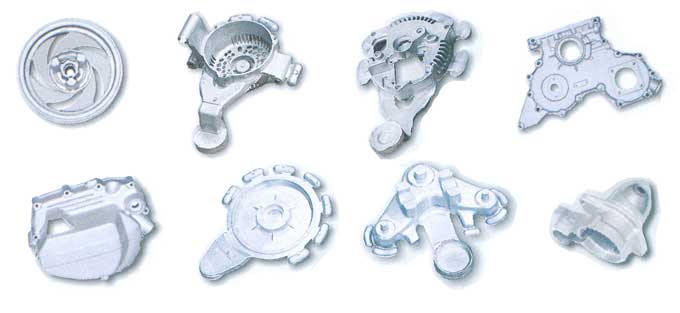

- The machine is widely used for mass production of foundry goods made of nonferrous metal such as aluminum, zinc and copper in the industries of automobiles, motorcycles, meters and instruments, household appliance hardware of daily necessities.

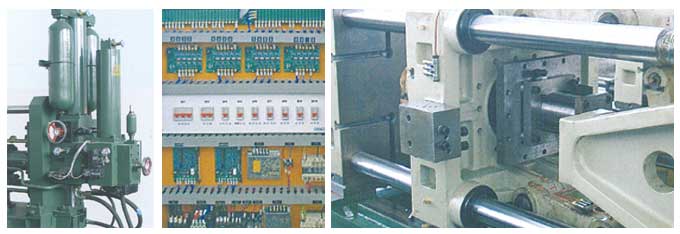

- Computer-programmed control, the trouble location and adjust of machine are remote controlled,via communication net, hydraulic drive adopts import proportional control valve for control, crank expanding structure,4-rod pilot elastic stress framework, locking that is tensile,faster and reliable, there are reliable security mechanism. The high precision electrical-machinary adjusting device adjusts the die height, 4-phase injection is afforded for fast injection speed, up to more than 6m/s, and minimum boosting less than 20ms, and individual control of injection and pressure intensification is possible. All parameters for injection may be adjusted separately against the requirements of producing qualified castings.3-tie bars connect the fixed plated with injection cylinder, thus there is larger operation space, this machine adopts advanced sealing structure parts and import sealling element.

- There are two kinds of driving methods as manual and link age.

- The machine is superior in performance and smooth in operation, it is advantageous in technology in mainland China, and can replace the import machine.

Description & Specification

| The project | The unit | HC500T | HC280T | HC180T | HC130T | HC63T | HC25T | ||||||||||||

| Die locking force | kN | 5000 | 2800 | 1800 | 1300 | 630 | 250 | ||||||||||||

| Size of moving platen(HxV) | mm | 1160X1080 | 900X930 | 720X719 | 660X667.5 | 480X480 | 400X400 | ||||||||||||

| Inner space between the bars (H x V) | mm | 760X660 | 610X580 | 480X480 | 430X430 | 300X300 | 240X240 | ||||||||||||

| Thickness of die block (Min./Max) | mm | 320/800 | 280/680 | 200/580 | 250/500 | 150/350 | 120/320 | ||||||||||||

| Stroke of moving platen | mm | 450 | 480 | 385 | 350 | 240 | 200 | ||||||||||||

| Ejection stroke | mm | 120 | 110 | 85 | 85 | 60 | 50 | ||||||||||||

| Ejection force | kN | 220 | 150 | 109 | 90 | 52 | 35 | ||||||||||||

| Injection force | kN | 500 | 340 | 230 | 150 | 90 | 35 | ||||||||||||

| Injection stroke | mm | 572 | 420 | 350 | 320 | 282 | 250 | ||||||||||||

| Injection position | mm | 0,-220 | 0,-160 | 0,-70,-140 | 0,-100 | 0,-60 | 0,-35 | ||||||||||||

| Diameter of shot sleeve | mm | 70 | 80 | 90 | 50 | 60 | 70 | 50 | 60 | 40 | 50 | 35 | 40 | 25 | 30 | ||||

| Dosage of fluid metal per shot (AL) | kg | 4.1 | 5.4 | 6.8 | 1.6 | 2.3 | 3.1 | 1.3 | 1.9 | 0.8 | 1.2 | 0.5 | 0.7 | 0.2 | 0.3 | ||||

| Injection Pressure | MPa | 130 | 99.5 | 78.6 | 153 | 106 | 78 | 117 | 81.3 | 119.4 | 76.4 | 93.5 | 71.6 | 71.3 | 49.5 | ||||

| Max.Projecting area of casting | cm2 | 636 | 359 | 221 | 152 | 110 | 50.5 | ||||||||||||

| Dry cycle | s | 12 | 10 | 7 | 7 | 5 | 4 | ||||||||||||

| Pipeline pressure | MPa | 14 | 14 | 13 | 12 | 10.5 | 7 | ||||||||||||

| Motor power | kW | 30 | 18.5 | 15 | 11 | 11 | 7.5 | ||||||||||||

| Machine weight | kg | 25000 | 12500 | 7000 | 5000 | 3500 | 2000 | ||||||||||||

| Overall dimensions (L x W x H) | mm | 7350X1950X3150 | 6600X1700X2900 | 5600X1280X2560 | 4800X1300X1800 | 3970X1050X2100 | 3030X1060X1300 | ||||||||||||

| Through Arcorom's continual development, variations in specifications and performance are subject to change without notice. | |||||||||||||||||||